Kutheni ibhetri ye-lithium ikhona into ephezulu yethiyori

Kwiibhetri ze-lithium-ion (LIBs), ezininzi ii-electrode ezisekelwe kwi-metal oxide zibonisa ngokungaqhelekanga umthamo wokugcina uphezulu ngaphaya kwexabiso labo lethiyori. Nangona le nto ichazwe ngokubanzi, iindlela ezisisiseko ze-physicochemical kwezi zinto zihlala zingenakwenzeka kwaye zihlala ziyingxoxo.

Iprofayile yeziphumo

Kutshanje, uNjingalwazi Miao Guoxing ovela kwiYunivesithi yaseWaterloo, eCanada, uNjingalwazi uYu Guihua ovela kwiYunivesithi yaseTexas eAustin, kunye noLi Hongsen noLi Qiang abavela kwiYunivesithi yaseQingdao ngokudibeneyo bapapashe iphepha lophando kwiMathiriyeli yeNdalo phantsi kwesihloko esithi "Umthamo owongezelelweyo wokugcina iibhetri ze-lithium-ion zesinyithi ezivezwe yi-situ magnetometry". Kulo msebenzi, ababhali abasetyenziswe kwi-situ magnetic monitoring ukubonisa ubukho bendawo eqinileyo ye-capacitance kwi-nanoparticles yensimbi kunye nokuba inani elikhulu lee-electron ze-spin-polarized zingagcinwa kwii-nanoparticles zetsimbi esele zincitshisiwe, ezihambelana ne-spatial charge mechanism. Ukongezelela, indlela yokuhlawulwa kwendawo eveziweyo inokwandiswa kwezinye iikhompawundi zetsimbi zenguqu, inika isikhokelo esibalulekileyo sokusekwa kweenkqubo zokugcinwa kwamandla aphezulu.

Iziphumo eziphambili zophando

(1) I-Fe eqhelekileyo yafundwa ngokusebenzisa i-in-situ magnetic monitoring technique3O4 / Evolution yesakhiwo sombane ngaphakathi kwebhetri ye-Li;

(2) ityhila ukuba i-Fe3O4In / Li inkqubo, umthamo wentlawulo yomhlaba ngumthombo oyintloko womthamo owongezelelweyo;

(3) I-surface capacitance mechanism ye-nanoparticles yensimbi inokwandiswa kuluhlu olubanzi lweengqungquthela zetsimbi zenguqu.

Isicatshulwa kunye nesikhokelo sokubhaliweyo

- Ukubonakaliswa kwesakhiwo kunye neempawu ze-electrochemical

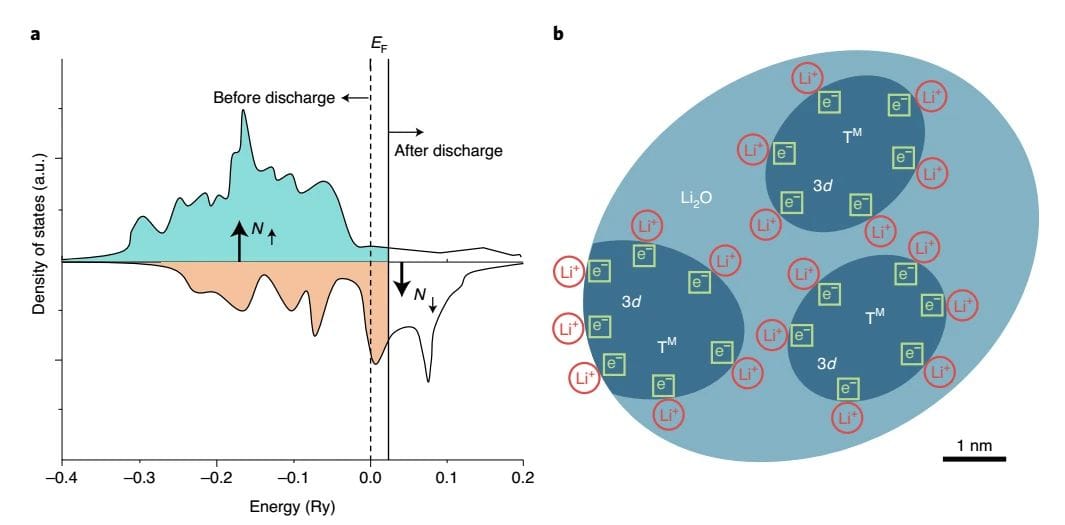

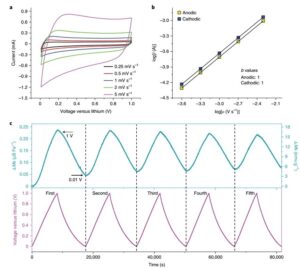

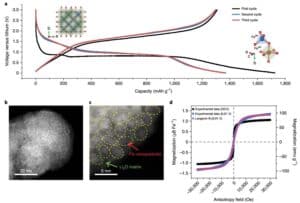

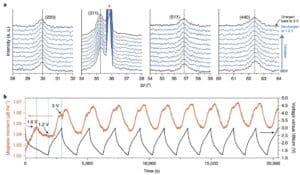

I-Monodisperse hollow Fe yadityaniswa ngeendlela eziqhelekileyo ze-hydrothermal3O4Nanospheres, kwaye emva koko yenziwa kwi-100 mAg−1Intlawulo kunye nokukhupha ngokuxinwa kwangoku (Umfanekiso 1a), umthamo wokuqala wokukhupha yi-1718 mAh g−1, 1370 mAhg ngokulandelelanayo kunye neyesithathu 1Kwaye 1,364 mAhg−1, Kude ngaphezulu kwe926 mAhg−1Ithiyori yokulindelweyo. Imifanekiso ye-BF-STEM yemveliso ekhutshwe ngokupheleleyo (Umfanekiso 1b-c) ibonisa ukuba emva kokunciphisa i-lithium, i-Fe3O4I-nanospheres yaguqulwa yaba yi-Fe nanoparticles encinci yokulinganisa malunga ne-1 - 3 nm, ihlakazwe kwiziko le-Li2O.

Ukubonisa utshintsho kwi-magnetism ngexesha lomjikelezo we-electrochemical, i-curve magnetization emva kokukhutshwa ngokupheleleyo kwi-0.01 V yafunyanwa (Umfanekiso we-1d), ebonisa ukuziphatha kwe-superparamagnetic ngenxa yokubunjwa kwe-nanoparticles.

Umzobo 1 (a) kwi-100 mAg−1Fe yebhayisikile kwi- density3O4 yangoku/ Intlawulo eqhubekayo yangoku kunye negophe lokukhutshwa kwebhetri ye-Li; (b) ngokupheleleyo i-lithium Fe3O4Umfanekiso we-BF-STEM we-electrode; (c) ubukho bukaLi kwi-aggregate2High-resolution ephezulu ye-BF-STEM imifanekiso yazo zombini i-O kunye ne-Fe; (d) Fe3O4I-hysteresis curves ye-electrode ngaphambi (emnyama) nasemva (ebhlowu), kunye ne-Langevin efakwe igophe lokugqibela (elimfusa).

- Ukufunyaniswa kwexesha lokwenyani lokuzivelela kolwakhiwo kunye nemagnethi

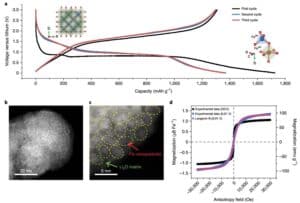

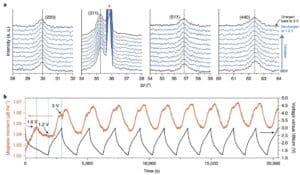

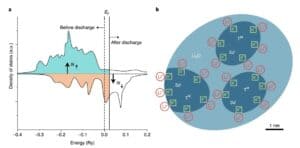

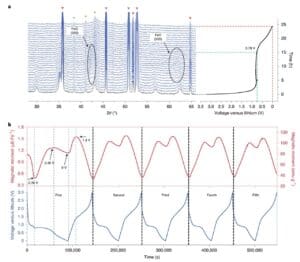

Ukuze kudityaniswe i-electrochemistry kunye ne-Fe3O4Of utshintsho lwesakhiwo kunye nemagnethi edityaniswe ne-Fe3O4I-Electrodes ziphantsi kwe-situ X-ray diffraction (XRD) kunye ne-situ magnetic monitoring. I-Fe kuluhlu lweepatheni ze-XRD ze-diffraction ngexesha lokukhutshwa kokuqala kwi-voltage ye-open-circuit (OCV) ukuya kwi-1.2V3O4Iincopho ze-diffraction azizange zitshintshe kakhulu nokuba kukuphi ukuqina okanye isikhundla (Umfanekiso 2a), ebonisa ukuba i-Fe3O4Only ifumene inkqubo ye-Li intercalation. Xa ihlawulwe kwi-3V, i-Fe3O4Isakhiwo se-anti-spinel sihlala sinjalo, sicebisa ukuba inkqubo kule festile yombane iguqulwa kakhulu. Ukubeka iliso okungaphaya kwi-situ magnetic kudityaniswe novavanyo oluqhubekayo lwangoku lokukhupha intlawulo lwenziwa ukuphanda ukuba imagnetization ivela njani ngexesha lokwenyani (Figure 2b).

Umzobo 2 Ukubonakaliswa kwe-in-situ XRD kunye nokujongwa kwemagnethi.(A) kwindawo XRD; (b) I-Fe3O4I-Electrochemical charge-discharge curve phantsi kwe-3 T isebenzise intsimi yamagnetic kunye ne-reversible reversible in situ magnetic response.

Ukufumana ukuqonda okusisiseko ngakumbi kule nkqubo yokuguqulwa ngokubhekiselele kwinguqu ye-magnetization, impendulo yamagnetic iqokelelwa ngexesha langempela kunye nenguqu yesigaba esihambelanayo ehamba kunye ne-electrochemically driven reactions (Umfanekiso 3). Kucacile ukuba ngexesha lokukhutshwa kokuqala, i-Fe3O4Impendulo ye-magnetization ye-electrode ihluke kwezinye iijikethi ngenxa ye-Fe ngexesha lokuqala le-lithalization3O4Ngenxa yenguqu yesigaba esingenakuguqulwa. Xa amandla awela kwi-0.78V, i-Fe3O4Isigaba se-antispinel saguqulwa ukuze sibe ne-Li2I-class FeO halite isakhiwo se-O, Fe3O4Isigaba asikwazi ukubuyiselwa emva kokutshaja. Ngokuhambelanayo, i-magnetization yehla ngokukhawuleza ukuya kwi-0.482 μ b Fe-1. Njengoko i-lithialization iqhubeka, akukho sigaba esitsha esenziweyo, kunye nobukhulu be-(200) kunye (220) iklasi ye-FeO diffraction peaks yaqala ukuba buthathaka.equal Fe3O4Akukho nto ibalulekileyo ye-XRD egciniweyo xa i-electrode i-liialized ngokupheleleyo (Umfanekiso 3a). Qaphela ukuba xa i-electrode ye-Fe3O4 ikhupha kwi-0.78V ukuya kwi-0.45V, i-magnetization (ukusuka kwi-0.482 μ b Fe-1Yandisiwe ukuya kwi-1.266 μ bFe-1), Oku kubangelwa ukuguqulwa kwenguqu ukusuka kwi-FeO ukuya kwi-Fe. Emva koko, ekupheleni kokukhutshwa, i-magnetization yancipha ngokukhawuleza ukuya kwi-1.132 μ B Fe-1. Oku kufunyanisiweyo kubonisa ukuba i-metal Fe0Nanoparticles encitshiswe ngokupheleleyo isenokuthatha inxaxheba kwi-lithium yokugcina impendulo, ngaloo ndlela inciphisa i-magnetization yee-electrodes.

Umzobo 3 Ukuqwalasela kwi-situ yenguqu yesigaba kunye nempendulo yamagnetic. (a) Fe3O4In situ XRD imephu eqokelelwe ngexesha lokuqala lokukhutshwa kwe-electrode; (b) I-Fe3O4In situ umlinganiselo wamandla kazibuthe wemijikelo ye-electrochemical ye/Li seli kwindawo esetyenziswayo yemagnethi ye-3 T.

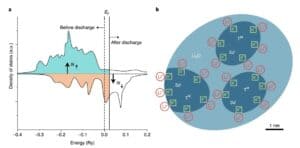

- I-Fe0/Li2Surface capacitance ye-O system

I-Fe3O4Utshintsho lwemagnethi yee-electrode lwenzeka kumbane ophantsi, apho amandla owongezelelweyo e-electrochemical kusenokwenzeka ukuba aveliswe, nto leyo ebonisa ubukho babathwali bentlawulo abangafunyaniswanga ngaphakathi kweseli. Ukuphonononga indlela yokugcina i-lithium enokubakho, i-Fe yafundwa nge-XPS, i-STEM kunye ne-magnetic performance spectrum3O4Electrodes ye-magnetization peaks kwi-0.01V, 0.45V kunye ne-1.4V ukufumanisa umthombo wokutshintsha kwamagnetic. Iziphumo zibonisa ukuba umzuzu wamagnetic yinto ephambili echaphazela utshintsho lwamagnetic, kuba i-Fe0 / Li2 elinganisiweyo ye-Ms ye-O inkqubo ayichatshazelwa yi-anisotropy yamagnetic kunye ne-interparticle coupling.

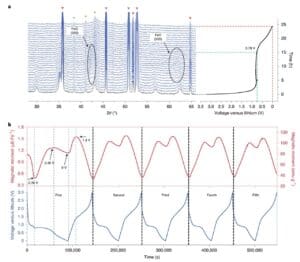

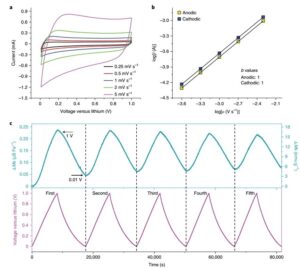

Ukuqonda ngakumbi i-Fe3O4Iimpawu ze-kinetic ze-electrode kwi-voltage ephantsi, i-voltammetry ye-cyclic kumazinga ahlukeneyo okuskena. Njengoko kubonisiwe kwi-Figure 4a, i-curve ye-cyclic voltammogram ye-rectangular ibonakala ngaphakathi koluhlu lwe-voltage phakathi kwe-0.01V kunye ne-1V (Umfanekiso 4a). Umzobo we-4b ubonisa ukuba impendulo ye-Fe3O4A ye-capacitive yenzeke kwi-electrode. Ngempendulo yamagnetic eguquguqukayo kakhulu yentlawulo eqhubekayo kunye nenkqubo yokukhupha (Umfanekiso 4c), i-magnetization ye-electrode yehla ukusuka kwi-1V ukuya kwi-0.01V ngexesha lenkqubo yokukhupha, kwaye yanda kwakhona ngexesha lenkqubo yokutshaja, ebonisa ukuba i-Fe0Of i-capacitor-like. ukusabela komphezulu kuguqulwa kakhulu.

Umzobo we-4 iimpawu ze-electrochemical kunye ne-situ magnetic characterization kwi-0.011 V. (A) Ijika le-voltammetric ye-cyclic. (B) ixabiso le-b lichongwa ngokusebenzisa ulungelelwaniso phakathi kwencopho yangoku kunye nesantya sokuskena; c

I-Fe3O4 ekhankanywe ngasentla I-electrochemical, i-structural kunye ne-magnetic features of electrodes ibonisa ukuba amandla ongeziweyo ebhetri anqunywe ngu-Fe0I-spin-polarized surface capacitance ye-nanoparticles ibangelwa utshintsho oluhamba kunye namagnetic. I-spin-polarized capacitance isiphumo se-spin-polarized charge accumulation kwi-interface kwaye ingabonisa impendulo yamagnetic ngexesha lokuhlawula kunye nokukhupha.to Fe3O4Isiseko se-electrode, ngexesha lenkqubo yokuqala yokukhupha, yachithwa kwi-Li2Fine Fe nanoparticles kwi-O substrate ibe umphezulu-to-volume ratios ezinkulu kwaye baqonde ingxinano eliphezulu amazwe kwinqanaba Fermi ngenxa yendawo kakhulu d orbitals. Ngokutsho kwemodeli yethiyori kaMaier yokugcinwa kwentlawulo yendawo, ababhali bacebisa ukuba izixa ezikhulu zee-electron zingagcinwa kwiibhendi eziqhekezayo ze-metallic Fe nanoparticles, ezinokufumaneka kwi-Fe / Li2Ukudala i-spin-polarized surface capacitors kwi-O nanocomposites. Umzobo 5).

Igrafu 5Fe/Li2A Umelo olucwangcisiweyo lobuchule bomphezulu beelektroni ezijikelezisiweyo ezijikelezisiweyo kwi-O-interface. (A) umzobo weschematic we-spin polarization state uxinaniso lomphezulu wamasuntswana esinyithi eferromagnetic (phambi nasemva kokukhutshwa), ngokuchaseneyo isambuku spin polarization yentsimbi; b

Isishwankathelo kunye ne-Outlook

I-TM / Li yaphandwa yi-in-situ yokuhlola magnetic2Ukuvela kwesakhiwo sangaphakathi se-elektroniki se-O nanocomposite ukuveza umthombo wogcino olongezelelweyo lwebhetri ye-lithium-ion. Iziphumo zibonisa ukuba, zombini kwi-Fe3O4 / Li imodeli ye-cell system, i-electrochemically yanciphisa i-Fe nanoparticles inokugcina inani elikhulu le-electron e-spin-polarized, okubangelwa ngenxa yobuninzi beeseli kunye nokuguqula kakhulu i-interfacial magnetism. Imilingo iphinde yaqinisekiswa i-CoO, i-NiO, kunye ne-FeF2 kunye ne-Fe2 Ubukho beso sixhobo kwi-N electrode imathiriyeli ibonisa ubukho be-spin-polarized surface capacitance ye-nanoparticles zesinyithi kwiibhetri ze-lithium ion kwaye kubeka isiseko sokusetyenziswa kwesi sixhobo sokugcinwa kwentlawulo yendawo kwenye inguqu. izinto ze-electrode ezisekelwe kwisinyithi.

Ikhonkco loncwadi

Umthamo owongezelelweyo wokugcina kwiibhetri ze-oxide ze-lithium-ion ezivezwe yi-situ magnetometry (Izinto zeNdalo , 2020, DOI: 10.1038 / s41563-020-0756-y)

Impembelelo ye-lithium electrode wafer design formula kunye ne-electrode wafer defects ekusebenzeni

- Inqaku lesiseko soyilo bhanyabhanya

I-lithium ibhetri ye-electrode yingubo ehlanganiswe ngamaqhekeza, ngokulinganayo isetyenziswe kwi-metal fluid. I-lithium ion ibhetri ye-electrode coating inokuthathwa njengento ehlanganisiweyo, ikakhulu yenziwe ngamacandelo amathathu:

(1) Amasuntswana ezinto ezisebenzayo;

(2) isigaba esisisiseko se-agent ye-conductive kunye ne-arhente (isigaba se-carbon adhesive);

(3) I-pore, gcwalisa i-electrolyte.

Ubudlelwane bomthamo wesigaba ngasinye bubonakaliswa ngolu hlobo:

I-Porosity + iqhezu lomthamo wento ephilayo + iqhezu lesigaba sokuncamathelisa ikhabhoni =1

Uyilo loyilo lwe-lithium ibhetri ye-electrode lubaluleke kakhulu, kwaye ngoku ulwazi olusisiseko lwe-lithium ibhetri yoyilo lwe-electrode luziswa ngokufutshane.

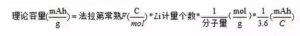

(1) Umthamo wethiyori wezinto ze-electrode Umthamo wethiyori wesixhobo se-electrode, oko kukuthi, amandla anikezwe yi-ion ze-lithium kwizinto ezibandakanyekayo kwi-electrochemical reaction, ixabiso layo libalwa ngolu hlobo lulandelayo:

Umzekelo, i-LiFePO4Ubunzima be-molar yi-157.756 g/mol, kunye nomthamo wayo wethiyori:

Eli xabiso libaliweyo lixabiso legram yethiyori kuphela. Ukuze kuqinisekiswe ukuguqulwa kwesakhiwo sezinto eziphathekayo, i-coefficient ye-lithium ion yokususwa kwe-ion ingaphantsi kwe-1, kunye nomthamo wangempela wegram wezinto eziphathekayo:

Eyona gram umthamo wezinto = umthamo wethiyori we-lithium ion unplugging coefficient

(2) Umthamo woyilo lwebhetri kunye noxinaniso kwicala elinye ngokugqithisileyo Umthamo woyilo lwebhetri unokubalwa ngale fomula ilandelayo: umthamo woyilo lwebhetri = ingxinano yomphezulu wento esebenzayo umlinganiselo osebenzayo wegram umthamo wepali yeshiti indawo yokwaleka.

Phakathi kwabo, ukuxinana komphezulu wengubo yiparameter yoyilo oluphambili. Xa ukuxinana koxinzelelo kungaguqukanga, ukwanda koxinzelelo lomphezulu wokutyabeka kuthetha ukuba ukutyeba kweshiti lepali kuyanda, umgama wokuhanjiswa kwe-electron uyanda, kwaye ukonyuka kwe-electron kuyanda, kodwa iqondo lokunyuka lilinganiselwe. Kwiphepha elishinyeneyo le-electrode, ukwanda kwe-impedance ye-lithium ion kwi-electrolyte sesona sizathu sichaphazela iimpawu zomlinganiselo. Ukuqwalasela i-porosity kunye ne-pore twists, umgama wokufuduka we-ion kwi-pore uphindwe kaninzi kunobunzima be-pole sheet.

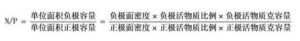

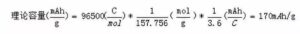

(3) Umyinge we-negative-positive capacity ratio N / P ye-negative capacity ukuya kwi-positive capacity ichazwa ngolu hlobo:

I-N / P kufuneka ibe nkulu kune-1.0, ngokubanzi i-1.04 ~ 1.20, eyona nto iphambili kuyilo lokhuseleko, ukuthintela i-ion ye-lithium engalunganga ukusuka kwimvula ngaphandle komthombo wokwamkelwa, uyilo lokuqwalasela umthamo wenkqubo, njengokutenxa kokutyabeka. Nangona kunjalo, xa i-N / P inkulu kakhulu, ibhetri iya kuphulukana nomthamo ongabuyisekiyo, okukhokelela kumthamo ophantsi webhetri kunye nokuhla kwamandla ebhetri.

Kwi-lithium titanate anode, i-electrode efanelekileyo yoyilo olugqithisileyo luyamkelwa, kwaye umthamo webhetri unqunywe ngumthamo we-lithium titanate anode. Uyilo olugqwesileyo oluncomekayo lunceda ekuphuculeni ukusebenza kobushushu obuphezulu bebhetri: ubushushu obuphezulu begesi ikakhulu buvela kwi-electrode engalunganga. Kuyilo oluhle olugqithisileyo, amandla angalunganga aphantsi, kwaye kulula ukwenza ifilimu ye-SEI kumphezulu we-lithium titanate.

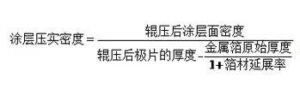

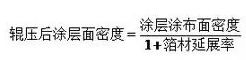

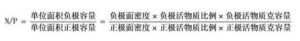

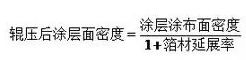

(4) Ukuxinana koxinzelelo kunye ne-porosity yengubo Kwinkqubo yokuvelisa, ukuxinana kwe-coating compaction ye-electrode yebhetri ibalwa ngolu hlobo lulandelayo. Ukuqwalasela ukuba xa i-pole sheet igqitywe, i-foil yensimbi iyandiswa, ukuxinwa kwendawo yokugubungela emva kokuba i-roller ibalwa ngolu hlobo lulandelayo.

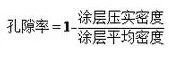

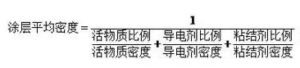

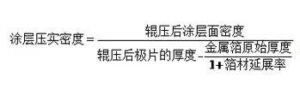

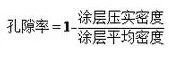

Njengoko bekutshiwo ngaphambili, i-coating ibandakanya isigaba sezinto eziphilayo, isigaba sokunamathela kwekhabhoni kunye ne-pore, kwaye i-porosity ingabalwa ngolu hlobo lulandelayo.

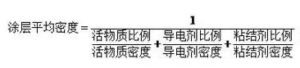

Phakathi kwabo, ukuxinana okuqhelekileyo kokugquma kukuba: i-lithium ibhetri ye-electrode luhlobo oluthile lwe-powder particles of coating, kuba i-particle powder surface rough, i-share shape, xa iqokelelwa, amasuntswana phakathi kwamasuntswana kunye namasuntswana, kwaye amanye amasuntswana ngokwawo aneentanda kunye neepores, ngoko umthamo we powder uquka umthamo we powder, iipores phakathi kwamaqhekeza empuphu kunye neengqungquthela, ngoko ke, iindidi ezihambelanayo ze-electrode coating density and porosity representation. Ubuninzi be-powder particles bubhekisela kubunzima bomgubo kwiyunithi nganye. Ngokomthamo wepowder, uhlukaniswe ube ziindidi ezintathu: ubuninzi bokwenene, ukuxinana kwamasuntswana kunye nobuninzi bokuqokelela. Uxinaniso olwahlukeneyo luchazwa ngolu hlobo lulandelayo:

- Uxinaniso lokwenyani lubhekiselele kubuninzi obufunyenwe ngokwahlula umgubo wobunzima ngomthamo (umthamo wangempela) ngaphandle kwezithuba zangaphakathi nangaphandle zamasuntswana. Oko kukuthi, ubuninzi bomcimbi ngokwawo obufunyenwe emva kokungabandakanyi umthamo wazo zonke i-voids.

- Uxinaniso lwesuntswana lubhekiselele kubuninzi bamasuntswana afunyenwe ngokwahlulahlula ubunzima bomgubo ohlulwe ngumthamo wamasuntswana oquka umngxuma ovulekileyo kunye nomngxuma ovaliweyo. Oko kukuthi, i-gap phakathi kweengqungquthela, kodwa kungekhona i-pores emihle ngaphakathi kweengqungquthela, ubuninzi beengqungquthela ngokwazo.

- Ubuninzi be-Accumulation, oko kukuthi, ukuxinana kweengubo, kubhekisela kubuninzi obufunyenwe ngumgubo ohlulwe ngumthamo wengubo eyenziwe ngumgubo. Umthamo osetyenzisiweyo uquka i-pores yeengqungquthela ngokwazo kunye ne-voids phakathi kweengqungquthela.

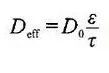

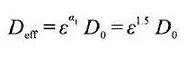

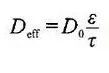

Kumgubo ofanayo, ubuninzi bokwenyani> ukuxinana kwamasuntswana> ukupakisha ukuxinana. I-porosity yomgubo ngumlinganiselo we-pores kwi-particle particle coating, oko kukuthi, umlinganiselo womthamo we-void phakathi kwamasuntswana omgubo kunye neepores zamasuntswana kumthamo opheleleyo wengubo, edlalwa ngokuqhelekileyo. njengepesenti. I-porosity yomgubo yipropati ebanzi ehambelana ne-particle morphology, umgangatho we-surface, ubungakanani be-particle size distribution size. I-porosity yayo ichaphazela ngokuthe ngqo ukungena kwe-electrolyte kunye ne-lithium ion transmission. Ngokuqhelekileyo, i-porosity enkulu, kulula ukungena kwe-electrolyte, kwaye ngokukhawuleza ukuhanjiswa kwe-lithium ion. Ngoko ke, ekuqulunqweni kwebhetri ye-lithium, ngamanye amaxesha ukucacisa i-porosity, isetyenziswa ngokuqhelekileyo indlela yoxinzelelo lwe-mercury, indlela ye-gas adsorption, njl. I-porosity inokuba neempembelelo ezahlukeneyo xa usebenzisa ingxinano eyahlukeneyo ekubaleni. Xa ubuninzi be-porosity yezinto eziphilayo, i-agent eqhubayo kunye ne-binder ibalwa ngoxinaniso lokwenyani, i-porosity ebalwayo ibandakanya i-gap phakathi kweengqungquthela kunye ne-gap ngaphakathi kweengqungquthela. Xa i-porosity yezinto eziphilayo, i-agent eqhubayo kunye ne-binder ibalwa nge-particle density, i-porosity ebalwayo ibandakanya i-gap phakathi kweengqungquthela, kodwa kungekhona i-gap ngaphakathi kweengqungquthela. Ngoko ke, ubukhulu bepore bephepha le-lithium ibhetri ye-electrode nayo i-multi-scale, ngokuqhelekileyo i-gap phakathi kwee-particles i-micron scale size, ngelixa i-gap ngaphakathi kwee-particles in the nanometer to sub-submicron scale. Kwii-electrode ezinamanzi, unxulumano lweepropathi zothutho ezifana ne-diffusivity esebenzayo kunye ne-conductivity inokubonakaliswa ngolu hlobo lulandelayo:

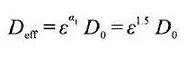

Apho i-D0 imele i-intrinsic diffusion (i-conduction) yezinga lezinto ngokwazo, ε iqhezu lomthamo wesigaba esihambelanayo, kwaye τ yi-curvature ejikelezayo yesigaba esihambelanayo. Kwimodeli ye-macroscopic ye-homogeneous, ubudlelwane be-Bruggeman busetyenziswa ngokubanzi, ukuthatha i-coefficient ɑ = 1.5 ukuqikelela i-positivity esebenzayo ye-electrodes e-porous.

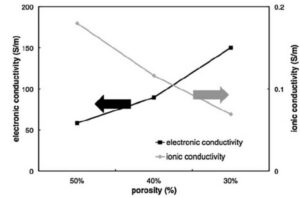

I-electrolyte izaliswe kwii-pores ze-electrodes ezinama-porous, apho i-lithium ion iqhutywe nge-electrolyte, kwaye iimpawu zokuqhuba ii-ion ze-lithium zihambelana ngokusondeleyo ne-porosity. Inkulu i-porosity, iphezulu iqhezu lomthamo wesigaba se-electrolyte, kunye ne-conductivity esebenzayo yee-ion ze-lithium. Kwiphepha le-electrode elilungileyo, ii-electron zihanjiswa ngesigaba sokunamathela kwekhabhoni, isahlulo somthamo wesigaba se-carbon adhesive kunye ne-detour ye-carbon adhesive phase inquma ngokuthe ngqo ukuqhuba okusebenzayo kwee-electron.

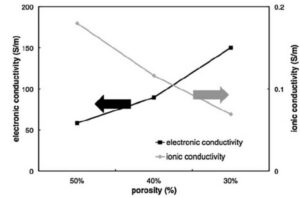

I-porosity kunye neqhezu lomthamo wesigaba se-carbon adhesive iyaphikisana, kwaye i-porosity enkulu ikhokelela ngokungenakunqandwa kwi-volume fraction of the carbon adhesive phase, ngoko ke, iipropathi ezisebenzayo zokuqhuba ii-ion ze-lithium kunye nee-electron nazo ziphikisana, njengoko kuboniswe kuMfanekiso 2. Njengoko i-porosity iyancipha, i-lithium ion conductivity esebenzayo iyancipha ngelixa i-electron conductivity esebenzayo isanda. Indlela yokulinganisa ezi zimbini nazo zibalulekile kuyilo lwe-electrode.

Umzobo 2 Umzobo weSchematic we-porosity kunye ne-lithium ion kunye ne-electron conductivity

2. Uhlobo kunye nokufumanisa iziphene zesibonda

Okwangoku, kwinkqubo yokulungiselela isibonda sebhetri, ngakumbi nangakumbi itekhnoloji yokuchongwa kwi-Intanethi yamkelwa, ukuze kuchongwe ngokufanelekileyo iziphene zokwenziwa kweemveliso, ukuphelisa iimveliso ezineziphene, kunye nengxelo efike ngexesha kumgca wemveliso, uhlengahlengiso oluzenzekelayo okanye lwezandla kwimveliso. inkqubo, ukunciphisa izinga elinesiphene.

Itekhnoloji yokukhangela kwi-intanethi edla ngokusetyenziswa kwimveliso ye-pali sheet ibandakanya ukubonwa kweempawu eziludaka, ukuchongwa komgangatho wepali, ukuchongwa komyinge, njalo njalo, Umzekelo: (1) imitha ye-viscosity ye-intanethi ifakwe ngokuthe ngqo kwitanki yokugcina ukutya ukuze ibone irheological. iimpawu ze-slurry ngexesha langempela, Vavanya ukuzinza kwe-slurry; (2) Ukusebenzisa i-X-ray okanye i-β -ray kwinkqubo yokwaleka, ukuchaneka kwayo okuphezulu komlinganiselo, Kodwa imitha enkulu, ixabiso eliphezulu lezixhobo kunye nenkathazo yokugcina; (3) Itekhnoloji yokulinganisa ubukhulu be-Laser kwi-intanethi isetyenziswa ukulinganisa ubukhulu beshiti lepali, ukuchaneka komlinganiselo kunokufikelela ± 1. 0 μ m, Ingabonisa kwakhona utshintsho lobunzima obulinganisiweyo kunye nobukhulu ngexesha lokwenyani, Yenza lula ukulandeleka kwedatha. kunye nohlalutyo; (4) Itekhnoloji yombono weCCD, oko kukuthi, uluhlu lweCCD lusetyenziselwa ukuskena into elinganisiweyo, Ukusetyenzwa komfanekiso wexesha lokwenyani kunye nohlalutyo lweendidi zesiphene, Qonda ukubhaqa okungonakalisi kwe-intanethi ye-pole sheet.

Njengesixhobo solawulo lomgangatho, itekhnoloji yovavanyo lwe-intanethi nayo ibalulekile ukuqonda unxulumano phakathi kweziphene kunye nokusebenza kwebhetri, ukuze kubonwe iindlela ezifanelekileyo / ezingafanelekanga kwiimveliso ezigqityiweyo.

Kwinxalenye yokugqibela, indlela entsha yokukhangela isiphene sobuchwephesha bebhetri ye-lithium-ion, iteknoloji ye-infrared imaging ye-thermal kunye nobudlelwane phakathi kwezi ziphene ezahlukeneyo kunye nokusebenza kwe-electrochemical kwaziswa ngokufutshane.bonisana noD. Mohanty Uphononongo olucokisekileyo nguMohanty et al.

(1) Iziphene eziqhelekileyo kumphezulu wepali

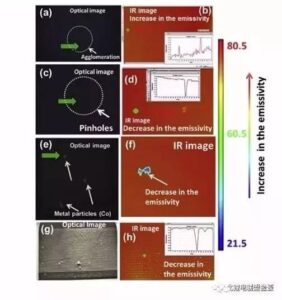

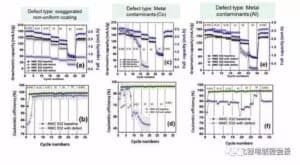

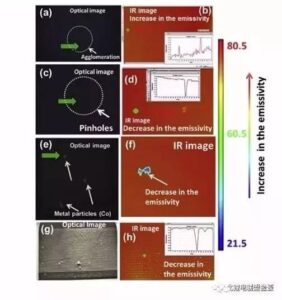

Umzobo we-3 ubonisa iziphene eziqhelekileyo kumphezulu we-lithium ion ibhetri ye-electrode, kunye nomfanekiso we-optical ngakwesobunxele kunye nomfanekiso obanjwe ngumfanekiso we-thermal ngakwesokudla.

Umzobo 3 Iziphene eziqhelekileyo kumphezulu we-pali sheet: (a, b) imvulophu ene-bulge / aggregate; (c, d) izinto zokuwisa / umngxuma wokujula; (e, f) umzimba wesinyithi wangaphandle; (g, h) Ukwaleka okungalinganiyo

(A, b) i-bulge ephakanyisiweyo / i-aggregate, iziphene ezinjalo zingenzeka ukuba udaka lushukunyiswa ngokulinganayo okanye isantya sokugquma asizinzanga. I-gregation ye-adhesive kunye ne-carbon black conductive agents ikhokelela kumxholo ophantsi wezithako ezisebenzayo kunye nobunzima obulula beepilisi ze-polar.

(c, d) ukuwisa / umngxuma, ezi ndawo zineziphene azigqunywanga kwaye zihlala ziveliswa ngamaqamza eludaka. Banciphisa inani lezinto ezisebenzayo kwaye baveze umqokeleli kwi-electrolyte, ngaloo ndlela banciphisa amandla e-electrochemical.

(E, f) imizimba yangaphandle yesinyithi, i-slurry okanye imizimba yesinyithi yangaphandle engeniswe kwisixhobo kunye nokusingqongileyo, kunye nemizimba yangaphandle yesinyithi inokubangela ingozi enkulu kwiibhetri ze-lithium. Iinqununu ezinkulu zetsimbi ziyonakalisa ngokuthe ngqo i-diaphragm, okubangelwa isiphaluka esifutshane phakathi kwe-electrodes efanelekileyo kunye ne-negative, eyisiphaluka esifutshane somzimba. Ukongeza, xa umzimba wesinyithi wangaphandle uxutywe kwi-electrode elungileyo, amandla afanelekileyo ayanda emva kokutshaja, isinyithi siyasombulula, sisasazeke nge-electrolyte, kwaye emva koko sityhalele kumphezulu ongalunganga, kwaye ekugqibeleni sigqobhoze i-diaphragm, senza isekethe emfutshane; eyikhemikhali yokupheliswa kwesekethe emfutshane. Imizimba yangaphandle yesinyithi eqhelekileyo kwindawo yebhetri yefektri yiFe, Cu, Zn, Al, Sn, SUS, njl.

(g, h) ukutyabeka okungalinganiyo, okufana nokudityaniswa koludaka akwanelanga, ukucoleka kwamasuntswana kulula ukuvela imivumbo xa isuntswana likhulu, okubangela ukugquma okungalinganiyo, okuya kuchaphazela ukuhambelana komthamo webhetri, kwaye nokuba kubonakale ngokupheleleyo. akukho mgca wokugquma, unefuthe kumthamo kunye nokhuseleko.

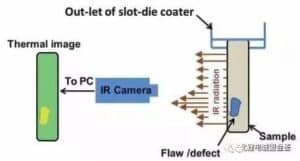

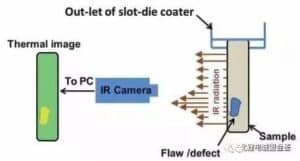

(2) Itekhnoloji yokufumanisa isiphene somgangatho wepoli ye-Infrared (IR) isetyenziselwa ukufumanisa iziphene ezincinci kwii-electrode ezomileyo ezinokonakalisa ukusebenza kweebhetri ze-lithium-ion. Ngethuba lokufunyanwa kwe-intanethi, ukuba i-electrode defect okanye ukungcola kufunyenwe, phawula kwiphepha le-pole, likhuphe kwinkqubo elandelayo, kunye nempendulo kumgca wokuvelisa, kwaye ulungelelanise inkqubo ngexesha lokuphelisa iziphene. Imitha ye-infrared luhlobo lwamaza ombane anendalo efanayo namaza erediyo kunye nokukhanya okubonakalayo. Isixhobo sombane esikhethekileyo sisetyenziselwa ukuguqula ukuhanjiswa kobushushu bomphezulu wento ibe ngumfanekiso obonakalayo weliso lomntu, kunye nokubonisa ukuhanjiswa kobushushu bomphezulu wento ngemibala eyahlukileyo kubizwa ngokuba yi-infrared thermal imaging technology. Esi sixhobo sombane sibizwa ngokuba yi-infrared thermal imager. Zonke izinto ezingaphezulu kweqanda (-273℃) zikhupha imitha ye-infrared.

Njengoko kubonisiwe kuMfanekiso 4, i-infrared thermal approximator (IR Camera) isebenzisa i-infrared detector kunye nenjongo yokujonga i-optical imaging ukwamkela ipateni yokuhambisa amandla emitha ye-infrared yento ekujoliswe kuyo kwaye iyibonise kwi-photosensitive element ye-infrared detector ukufumana umfanekiso we-infrared thermal, ohambelana nentsimi yokusabalalisa i-thermal kumphezulu wento. Xa kukho isiphene kumphezulu wento, ubushushu butshintsha kwindawo. Ke ngoko, le teknoloji ingasetyenziselwa ukufumanisa iziphene kumphezulu wento, ngokukodwa ifanelekileyo kwezinye iziphene ezingenako ukwahlula ngeendlela zokubona ukukhanya. Xa i-electrode yokumisa ibhetri ye-lithium ion ifunyenwe kwi-intanethi, i-electrode electrode iqala ukuhlanjululwa yi-flash, ubushushu bobushushu bomhlaba buguquka, kwaye emva koko ubushushu bomhlaba bufunyenwe ngomfanekiso we-thermal. Umfanekiso wokusasazwa kobushushu ubonwa, kwaye umfanekiso ucutshungulwa kwaye uhlalutywe ngexesha langempela ukuze ukhangele iziphene zomhlaba kwaye uziphawule ngexesha.D. I-Mohanty Uphononongo lufake umzobo we-thermal kwi-outlet ye-coater yomisa i-oven ukuze ibone umfanekiso wokusabalalisa ubushushu bomgangatho weshidi le-electrode.

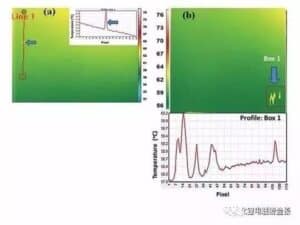

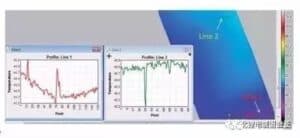

Isazobe sesi-5 (a) yimephu yokusasazwa kobushushu bomphezulu wokwaleka we-NMC yeshiti yepali echanekileyo efunyenwe ngumfanekiso we-thermal, equlethe isiphene esincinci kakhulu esingenako ukwahlulwa ngeliso lenyama. I-curve yokusabalalisa iqondo lokushisa elihambelana necandelo lendlela liboniswa kwi-inset yangaphakathi, kunye ne-spike yeqondo lokushisa kwindawo yesiphene. Kwi-Figure 5 (b), iqondo lokushisa liyanda kwindawo kwibhokisi ehambelanayo, ehambelana nesiphene somgangatho we-pole sheet. IKHIWANE. I-6 ngumzobo wokusabalalisa ubushushu bomhlaba wephepha le-electrode elibi elibonisa ubukho beziphene, apho ukuphakama kweqondo lokushisa kuhambelana ne-bubble okanye i-aggregate, kwaye indawo yokushisa iyancipha ihambelana ne-pinhole okanye i-drop.

Umzobo 5 Ukuhanjiswa kobushushu bomgangatho wephepha le-electrode elungileyo

Umzobo 6 Ukuhanjiswa kobushushu bomgangatho ongalunganga we-electrode

Ingabonwa ukuba ukubonwa kwe-thermal imaging yokusabalalisa ubushushu kuyindlela efanelekileyo yokubona i-pole sheet surface defect, engasetyenziselwa ukulawula umgangatho wokuvelisa i-pole sheet.3. Isiphumo sokusilela kweshiti lepali ekusebenzeni kwebhetri

(1) Impembelelo kumthamo wokuphindaphinda ibhetri kunye nokusebenza kakuhle kweCoulomb

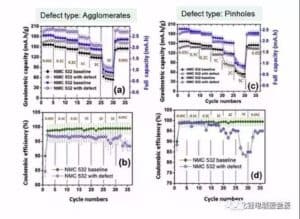

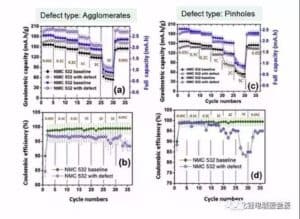

Umzobo we-7 ubonisa i-curve yempembelelo ye-aggregate kunye ne-pinhole kumthamo wokuphindaphinda ibhetri kunye nokusebenza kakuhle kwe-coulen. I-aggregate inokuphucula amandla ebhetri, kodwa yehlise ukusebenza kwe-coulen. I-pinhole inciphisa amandla ebhetri kunye nokusebenza kwe-Kulun, kunye nokusebenza kwe-Kulun kuncipha kakhulu kwizinga eliphezulu.

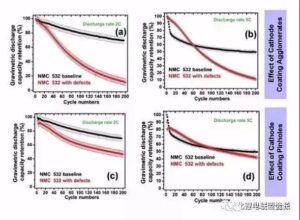

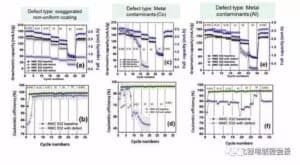

Figure 7 cathode aggregate kunye nesiphumo pinhole kwi umthamo ibhetri kunye nokusebenza kakuhle umzobo 8 ukutyabeka ngokungalinganiyo, kunye nentsimbi umzimba wangaphandle Co kunye Al kwi umthamo ibhetri kunye nesiphumo ijiko esebenzayo, ukutyabeka ngokungalinganiyo ukunciphisa iyunithi yebhetri umthamo umthamo 10% - - I-20%, kodwa amandla ebhetri yonke yehla nge-60%, oku kubonisa ukuba ubunzima obuphilayo kwiqhekeza le-polar buncitshiswe kakhulu. I-Metal Co umzimba wangaphandle unciphise umthamo kunye nokusebenza kakuhle kwe-Coulomb, nakwi-2C kunye ne-5C yokukhulisa okuphezulu, akukho mthamo konke konke, okunokuthi kube ngenxa yokwenziwa kwesinyithi kwi-electrochemical reaction ye-lithium kunye ne-lithium efakwe, okanye inokuba ngamasuntswana esinyithi. ivalwe i-diaphragm pore yabangela i-micro short circuit.

Umzobo we-8 Iziphumo ze-electrode entle engalinganiyo yokwaleka kunye nemizimba yesinyithi yangaphandle Co kunye ne-Al kumthamo wokuphindaphinda ibhetri kunye nokusebenza kakuhle kwecoulen

Isishwankathelo se-cathode sheet defects: I-ates kwi-cathode sheet coating inciphisa ukusebenza kakuhle kwe-Coulomb yebhetri. Umngxuma we-coulomb owenziwe kakuhle unciphisa ukusebenza kakuhle kwe-Coulomb, okukhokelela ekusebenzeni kakubi kophindaphindo, ngakumbi kuxinaniso oluphezulu lwangoku. I-heterogeneous coating ibonise ukusebenza kakubi kokukhulisa. Izinto ezingcolisa amasuntswana esinyithi zinokubangela iisekethe ezimfutshane ezincinci, kwaye ke zinokunciphisa kakhulu umthamo webhetri.

Umzobo we-9 ubonisa impembelelo yomgca we-foil ovuzayo ongalunganga kumthamo wokuphindaphinda kunye nokusebenza kakuhle kweKulun kwebhetri. Xa ukuvuza kwenzeka kwi-electrode embi, umthamo webhetri uyancipha kakhulu, kodwa umthamo wegram awubonakali, kwaye impembelelo ekusebenzeni kweKulun ayibalulekanga.

Umzobo 9 Impembelelo yomgca wefoyile ovuzayo we-electrode kumthamo wophindaphindo lwebhetri kunye nempumelelo yeKulun (2) Impembelelo ekusebenzeni komjikelo wokuphindaphinda ibhetri Umzobo 10 sisiphumo sempembelelo yesiphene somphezulu we-electrode kumjikelo wophindaphindo lwebhetri. Iziphumo zempembelelo zishwankathelwa ngolu hlobo lulandelayo:

I-Egregation: kwi-2C, izinga lokugcinwa kwamandla emijikelezo ye-200 yi-70% kunye nebhetri ephosakeleyo yi-12%, ngelixa kumjikelezo we-5C, izinga lokugcinwa komthamo we-200 cycles yi-50% kunye nebhetri ephosakeleyo yi-14%.

I-Needlehole: ukuthotywa kwamandla kuyabonakala, kodwa akukho kuncipha kwesiphako esipheleleyo ngokukhawuleza, kunye nesantya sokugcinwa komthamo we-200 cycle 2C kunye ne-5C yi-47% kunye ne-40%, ngokulandelanayo.

Umzimba weMetal wangaphandle: umthamo wesinyithi Co umzimba wangaphandle uphantse ube yi-0 emva kwemijikelo emininzi, kwaye umthamo womjikelo we-5C womzimba wesinyithi wangaphandle weAl foil uyancipha kakhulu.

Umcu wokuvuza: Kwindawo yokuvuza efanayo, umthamo webhetri wemigca emincinci emininzi uyancipha ngokukhawuleza kunomgca omkhulu (47% kwimijikelo engama-200 kwi-5C) (7% kwimijikelo engama-200 kwi-5C). Oku kubonisa ukuba inani elikhulu lemigca, impembelelo enkulu kumjikelo webhetri.

Umzobo we-10 Impembelelo ye-electrode sheet iziphene kumjikelo wereyithi yeseli

Ref.: [1] Uvavanyo olungonakaliyo lwe-slot-die-coated lithium i-battery yesibini ye-lithium nge-in-line laser caliper kunye neendlela ze-IR thermography [J].UHLAZIYO. yeziphene zokuvelisa i-electrode kwi-electrochemical performance ye-lithium-ion iibhetri: Ukuqaphela imithombo yokusilela kwebhetri [J] .Journal of Power Sources.2014, 6: 3-674.